Unveiling the Distinctions: Gray Iron vs. Ductile Iron

Release time:

2024-02-22

When it comes to the realm of cast iron, two prominent players take the stage: gray iron and ductile iron. While sharing a common heritage, these alloys possess unique characteristics that render them suitable for diverse applications. At Yaqi Casting, we delve into the nuances of these materials to help you make informed decisions for your projects.

Performances:

Formation and Carbon Structure:

Gray iron and ductile iron are cast iron alloys, yet their carbon structures set them apart. Gray iron showcases graphite in a flake-shaped pattern, imparting distinctive properties to the material. On the other hand, ductile iron's graphite assumes nodular or spherical forms, enhancing its flexibility and resilience.

Ductility and Strength:

One of the defining differences between gray iron and ductile iron is their ductility and strength. With its nodular graphite configuration, ductile iron exhibits significantly higher ductility than gray iron. This translates to enhanced flexibility and resilience, making ductile iron a preferred choice for applications requiring robustness and durability.

Impact Resistance and Thermal Conductivity:

Ductile iron boasts superior impact resistance, capable of withstanding considerably higher impact loads than gray iron. Gray iron's higher thermal conductivity makes it suitable for applications requiring efficient heat transfer. These distinct properties play a crucial role in determining the suitability of each material for specific applications.

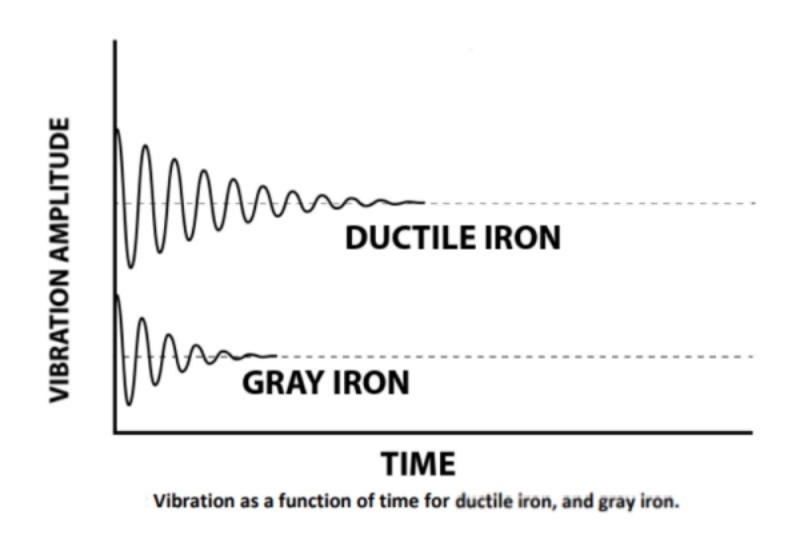

Vibration Damping:

Gray iron excels in damping vibrations, making it ideal for machinery components requiring vibration reduction. This attribute stems from its unique graphite structure, contributing to its damping capacity. Understanding these nuances enables engineers and designers to select the appropriate material based on the specific requirements of their projects.

Applications:

While both gray iron and ductile iron have their respective strengths and applications, ductile iron emerges as the upgraded alternative, offering superior mechanical properties and versatility. From automotive components to hydraulic systems and heavy machinery, ductile iron finds extensive use in critical applications where strength and ductility are paramount.

Yaqi Casting: Your Partner in Customized Casting Solutions

At Yaqi Casting, we specialize in delivering customized casting solutions tailored to meet your unique requirements. Whether you require gray iron or ductile iron components, our team of experts is committed to providing high-quality, precision-engineered solutions that exceed your expectations.

Conclusion:

In the dynamic world of casting, understanding the differences between gray iron and ductile iron is crucial for making informed decisions. Each material brings unique properties and advantages to the table, catering to diverse applications across industries. With Yaqi Casting by your side, you can trust our expertise to deliver customized casting solutions that meet your exact specifications and exceed your expectations.

Ready to elevate your projects with premium-quality cast iron components? Contact Yaqi Casting today to discuss your casting needs and discover how our customized solutions can enhance the performance and durability of your applications. Let us be your partner in bringing your designs to life with precision and excellence.

Key words:

Recommended News