What is the difference between SG iron and cast iron?

Release time:

2024-01-08

What is the difference between SG iron and cast iron? Which one is better? How should I choose?

SG Iron, or Spheroidal Graphite Iron, is a specific type of cast iron. The choice between SG Iron and other cast iron forms depends on your application's specific requirements. Here are some factors to consider when deciding between SG Iron and traditional cast iron:

1. Graphite Structure:

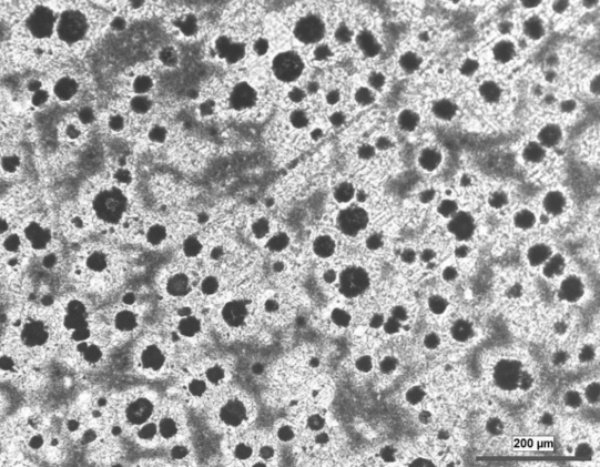

- SG Iron: It has a nodular graphite structure, which imparts better mechanical properties, such as higher tensile strength, toughness, and ductility. The spherical nodules in SG Iron provide improved resistance to crack propagation compared to other types of cast iron.

- Cast Iron: Traditional cast iron may have different graphite structures, including flakes or compacted graphite. While these structures offer good casting properties and wear resistance, they may lack the ductility and toughness of SG Iron.

2. Mechanical Properties:

- SG Iron: Offers superior mechanical properties, making it suitable for applications where strength, ductility, and impact resistance are important. It is often chosen for components subjected to dynamic loads.

- Cast Iron: Depending on the type, cast iron can have varying mechanical properties. It is known for good compressive strength and wear resistance but may not match SG Iron in terms of tensile strength and impact resistance.

3. Applications:

- SG Iron: Commonly used in applications where a combination of strength, ductility, and impact resistance is critical. This includes components in the automotive industry, engineering machinery, and certain pipe fittings.

- Cast Iron: Widely used in applications such as pipes, cookware, engine blocks, and ornamental structures. The choice depends on the specific demands of the application.

4. Cost:

- SG Iron: The production process for SG Iron may involve additional steps, and the alloying elements used can affect the cost. It might be more expensive than some traditional cast iron grades.

- Cast Iron: Traditional cast iron may be more cost-effective in certain applications, especially if the specific mechanical properties of SG Iron are not necessary.

5. Consultation with Experts:

- Material Engineers: If you're unsure about the best material for your application, consult with materials engineers or experts who can analyze your specific requirements and guide you in choosing the most suitable material.

When deciding between SG Iron and traditional cast iron for your application, it's essential to consider the specific demands and priorities of your project. SG Iron, with its nodular graphite structure, offers enhanced mechanical properties, including higher tensile strength, toughness, and ductility. This makes it particularly suitable for components subjected to dynamic loads or applications where crack resistance is crucial. However, it's important to note that the production process for SG Iron may involve additional steps, potentially impacting the overall cost.

On the other hand, traditional cast iron, with its diverse graphite structures, is well-known for good casting properties, wear resistance, and cost-effectiveness. Depending on your project requirements, a specific type of cast iron may offer the desired combination of properties at a more budget-friendly cost.

Ultimately, the choice between SG Iron and traditional cast iron should be based on a comprehensive analysis of your application's needs, considering factors such as mechanical performance, cost considerations, and the specific challenges the components may face. Consulting with materials engineers or experts in the field can provide valuable insights and help you make an informed decision tailored to your unique circumstances.

Key words:

Recommended News